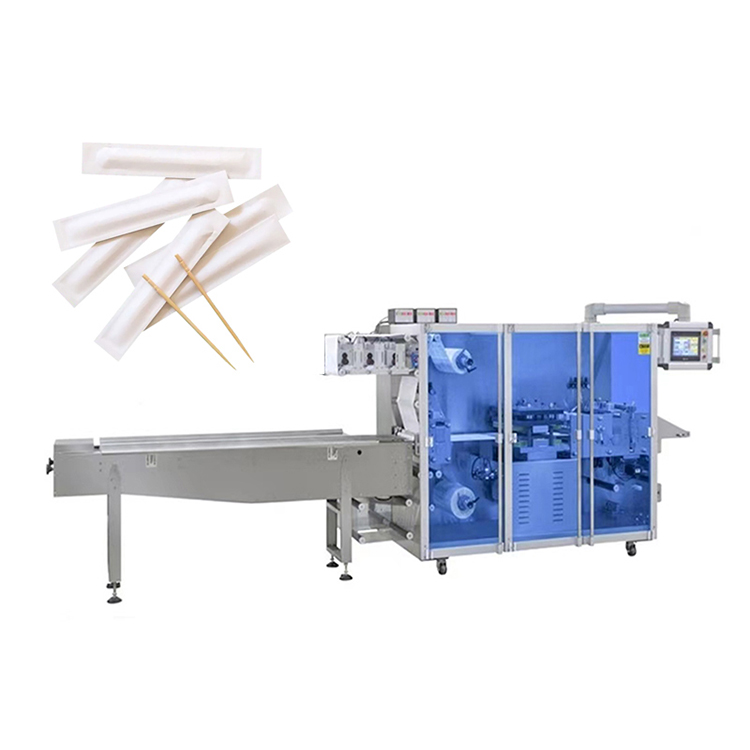

DLL-320 High Speed Automatic Strip Packaging Machine

- Place of Origin:

- Zhejiang, China

Summarize

The requirement for the medicine package is more higher because of high speed development of medicine industry. To suit development, our company successly developed new high-tech quality machine which is designed on the basis of comparison with the same type machine (DLL-160 and DLL-240) by our technician. The main function: Automatic feeding, crisp remove, material automatic filling, high speed heat-sealing, vertical and horizontal perforation, batch number printing, product cutting, defective sorting, finished product counting, waste material dispose, product output.

This machine is suitable for medicine, chemical, food requirement, it can higher product level and guarantee period, is new ideal automatic packaging equipment.

This machine compares the mechanical features of the old packing machine, and innovating the design of all servo motor traction:

1.Each mechanism adopt independent power unit, servo drive, PLC control, to ensure synchronism and steady at high speed running

2.Material controlling is different according to the shape of the material: Using ratchet mechanism or cam mechanism to control material, with servo drive, PLC control, can effective higher feeding speed to meet machine high speed running.

3.The diameter of heat pressing cam can be changed between 90-130mm, easy to change different specification.

4.Heating thermometric parts adopt infrared checking, PLC control, Effectively prevent the mold wheel from running at high temperature, resulting in the loss of the surface temperature of the mould wheel, resulting in the temperature drop of the heat seal, the unfirm adhesion and the virtual sticky phenomenon. Ensure the heat sealing effect of the plate. Ensure the finished product to be 100% qualified.

5.Product feeding adopt roll cutting feeding, servo drive, PLC control, can effective raise machine speed and ensure synchronism and steady.

6.Waste detection: automatic detection and sorting through high density detection device.

7.Waste material mechanism adopt roll cutting type, convenient for waste material recycle.

8.This machine suitable for AL/PL laminated foil packaging, also suitable for Paper/Foil or thin film/thin plastic film package.

9.This machine design novel, beautiful, the cover consist of armoured glass and aluminum alloy frame to higher product level.

Packaging materials

polyethylene chloride thin film, aluminum-plastic composite film, paper-plastic-aluminum composite film, dialysis paper etc.

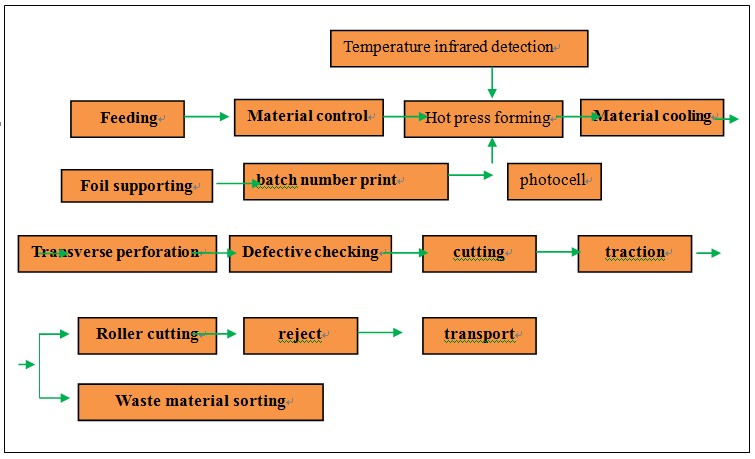

Basic Process

Main Technical Parameter

|

Speed of drum |

4-11m/min |

|

Packing Specification |

320mm |

|

AL/PL Laminated Foil |

0.08×320mm(Max) |

|

Electrothermal Power |

4kw |

|

Main Motor Power |

2.2kw |

|

Overall Dimension |

1890 *1120*2200mm |

|

Weight |

1700Kg |

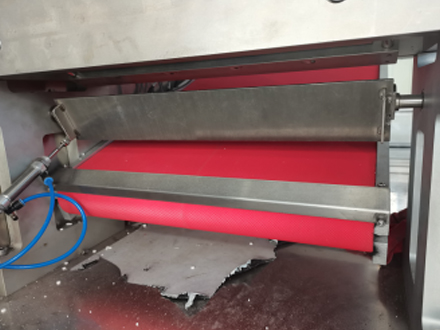

Machine Picture

Machine Picture

|

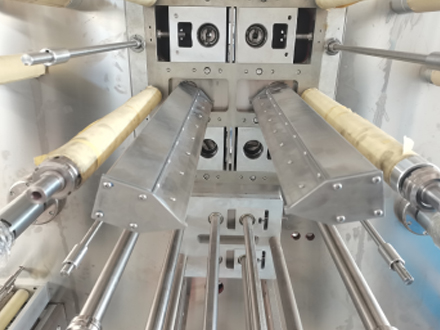

Feeding Device |

Feeding Device |

Material Control |

|

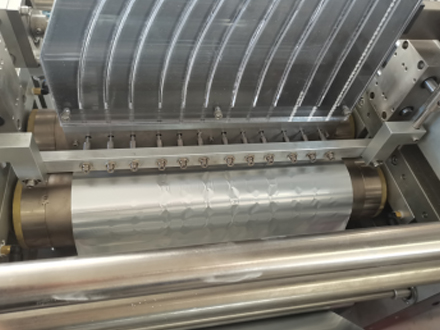

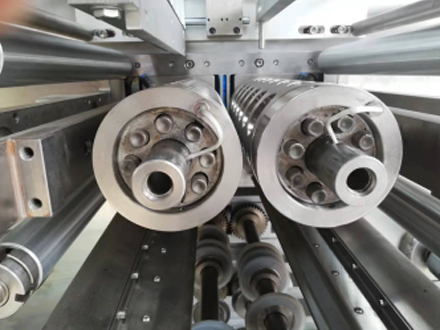

Hot Press Roller |

Material Cooling |

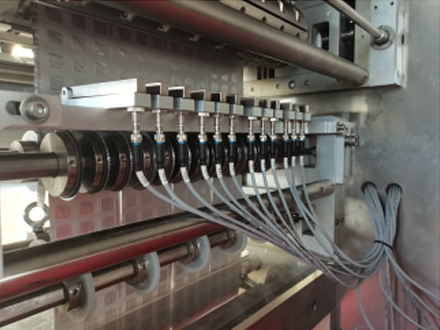

Automatic Detection Device |

|

Rejection Place |

Cutting and Traction |

Output Convey Belt |