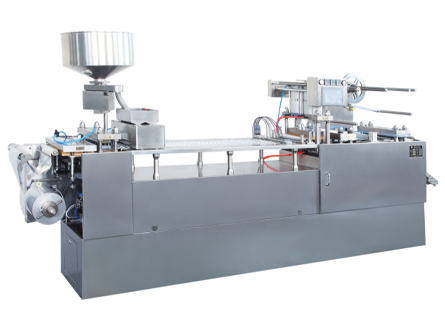

DPB-250B-I Blister Packaging Machine

- Place of Origin:

- Zhejiang, China

It is the latest generation product in our company which adopting PLC Human Interface, with frequency Converter, high automation, easy operation, novel figure, all-round-functions, advanced technology, stable running, durable life, conforms to "GMP Standard". It is an ideal blister packaging machine for AL/PL, AL/AL, Paper/PL packaging. It has passed Province technology production authentication.

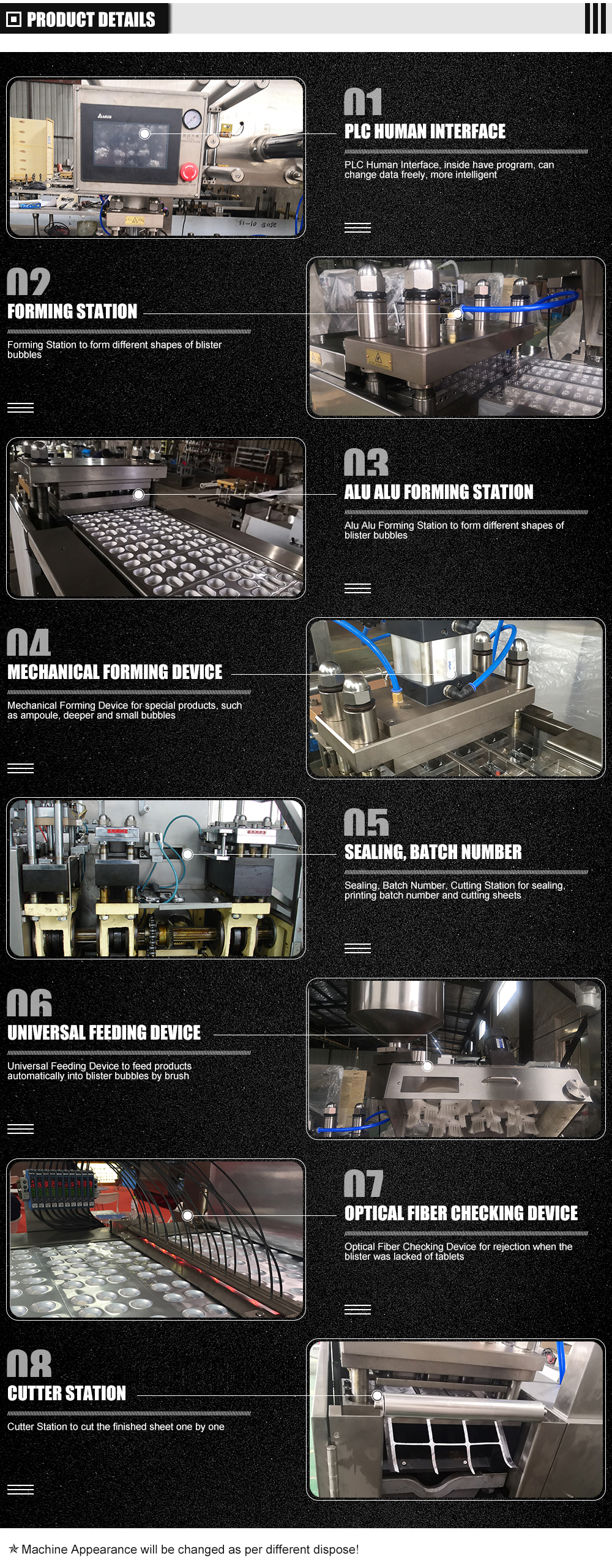

FEATURES

1. Equipped with inductive self-checking mechanism, it can eliminate the waste plate with lack of particle, the qualified rate reaches 100%. (option)

2. The heat sealing station is fixed, the distances between forming, perforation and punching etc. Units can be adjusted freely on the same plane and it is suitable for all kinds of dimensions with high precision, strong adaptability.

3. Flat structure, registration heating, mechanic(positive pressure) forming, up and down net web, cylinder heating sealing , manipulator draw, adjustable stroke, lower noise and steady of operation.

4. Main transmission adopts imported gear reducer, with excellent performance, lower noise, long life, stable operation.

5. Cursor tracking register, sealing with tidiness and good-looking appearance. (The body can be manufactured separately in order to easily transport the machine into workshop). (Option)

6. It can be equipped with optical fiber or photographing checking device according to the customers' requirements.

Main Technical Parameters

|

Cutting Frequency (Times/min) |

AL/AL 20-30, Al/plastic paper/plastic 25-35 |

|

Max. Forming area and depth (mm) |

AL/AL:240×150×9 AL/PL: 240×150×26 |

|

Stroke (mm) |

40-160 can be manufactured as user's requirements |

|

Standard Plate(mm) |

80×57 can be manufactured as user's requirements |

|

Air Pressure(Mpa) |

0.4-0.6 |

|

Air supply |

≥0.3 m³/min |

|

Total Power |

380V/220V 50Hz 6.2kw |

|

Main Motor Power (kw) |

1.5 |

|

Forming Aluminum(mm) |

0.085-0.1×250 |

|

PVC Hard Pieces(mm) |

0.15-0.5×250 |

|

PTP Aluminum Foil(mm) |

0.02-0.035×250 |

|

Dialysis Paper(mm) |

50-100g×250 |

|

Mould Cooling |

tap water or recycling water |

|

Overall Dimensions(mm) |

2710×720×1600(L×W×H) |

|

Weight (kg) |

1600 |

|

|

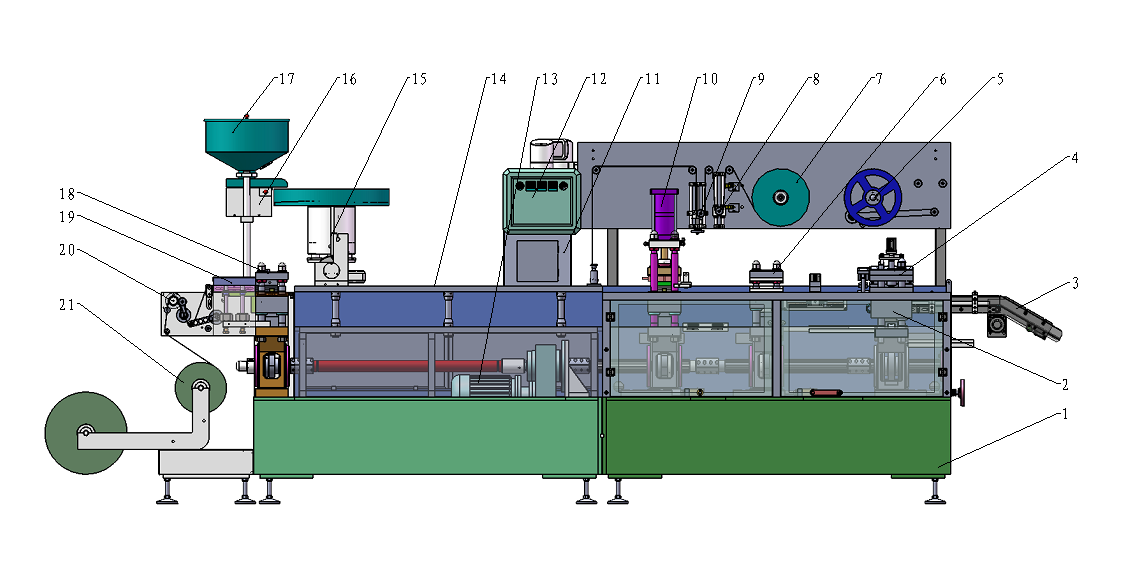

Note: Machine Appearance will be changed as per different dispose!

1.Machine Frame 2.Cutter Station 3.Rejection Convey Belt (OPTION) 4.Cutter Mould 5.Waste Material Recycle 6.Perforation Batch Number Station 7.PTP Alu Foil 8.Balance Roller 9.Eye Mark Switch (OPTION) 10.Heat-sealing Station 11.Photography Detection Station (OPTION) 12.Operation Panel 13.Main Motor 14.Working Table 15.Vibration Feeder 16.First Class Vibration Screen 17.Hopper 18. Forming Station 19.Forming Heating Part 20.Forming Alu Feeding Roller 21.Forming Alu