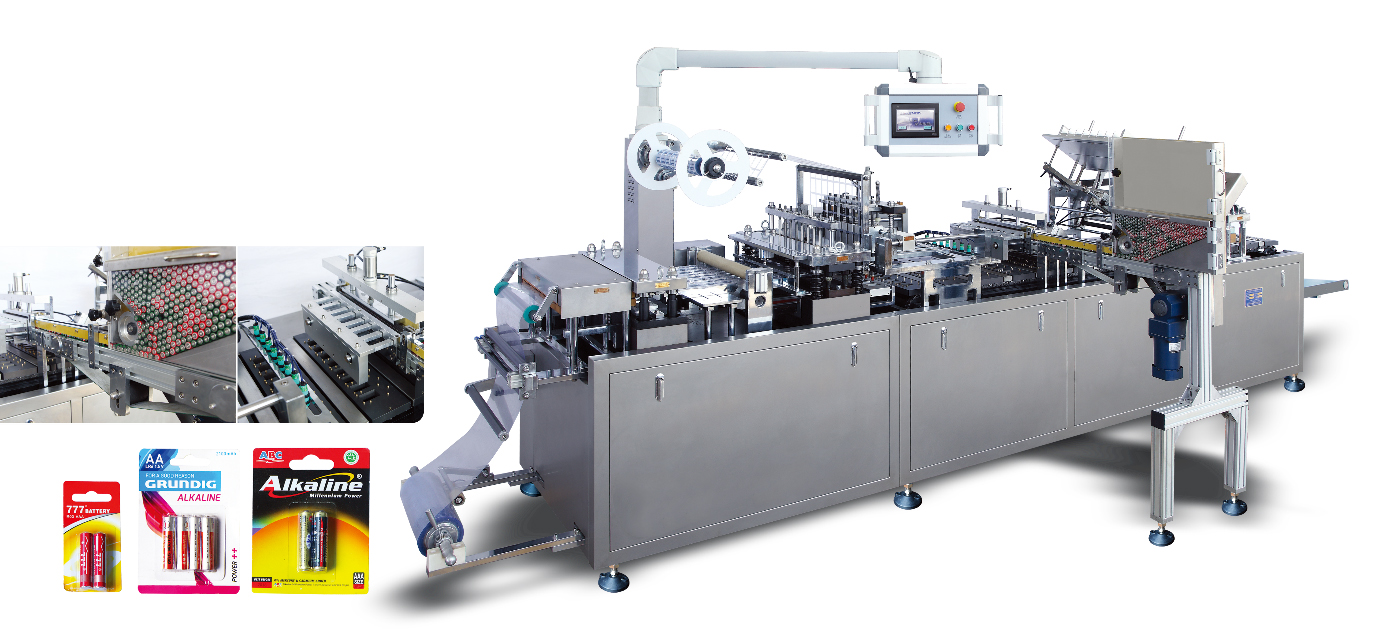

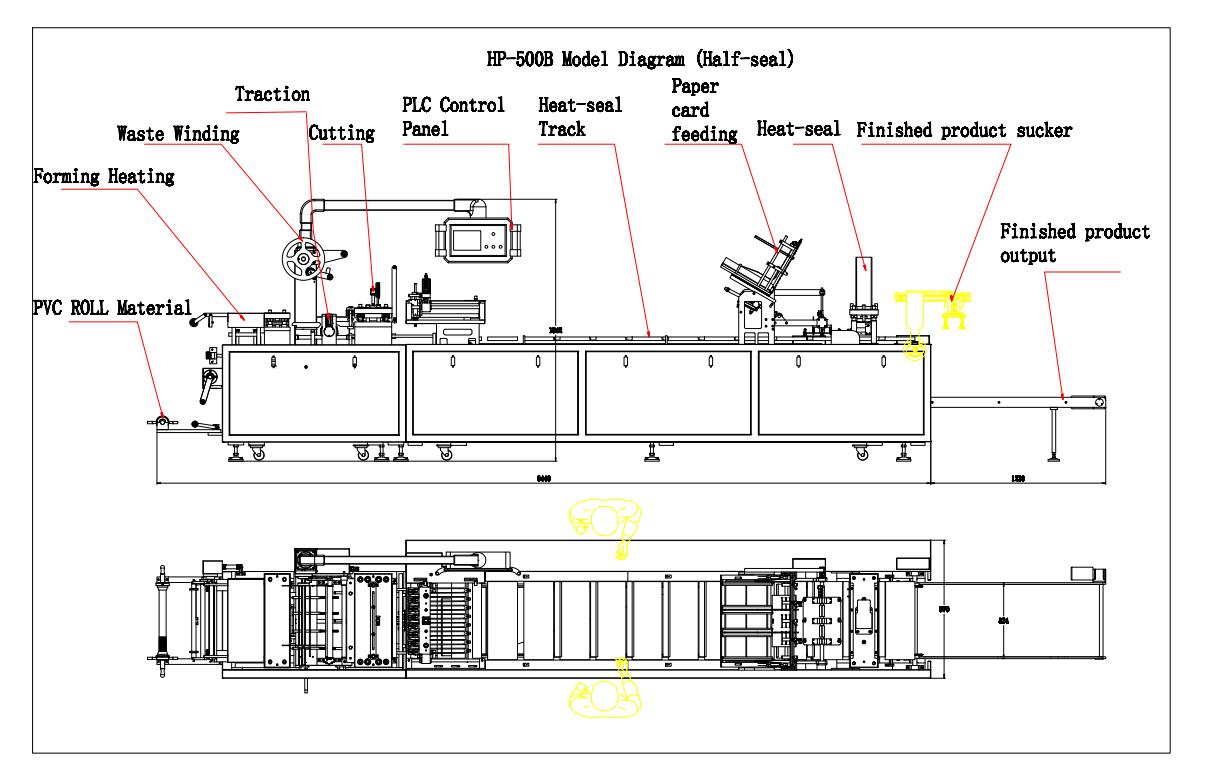

HP-500 High Frequency Plastic Paper Blister Card Heat Sealing Packing Machine

- Place of Origin:

- Zhejiang, China

High Frequency Plastic Paper Blister Card Heat Sealing Packing Machine Scope

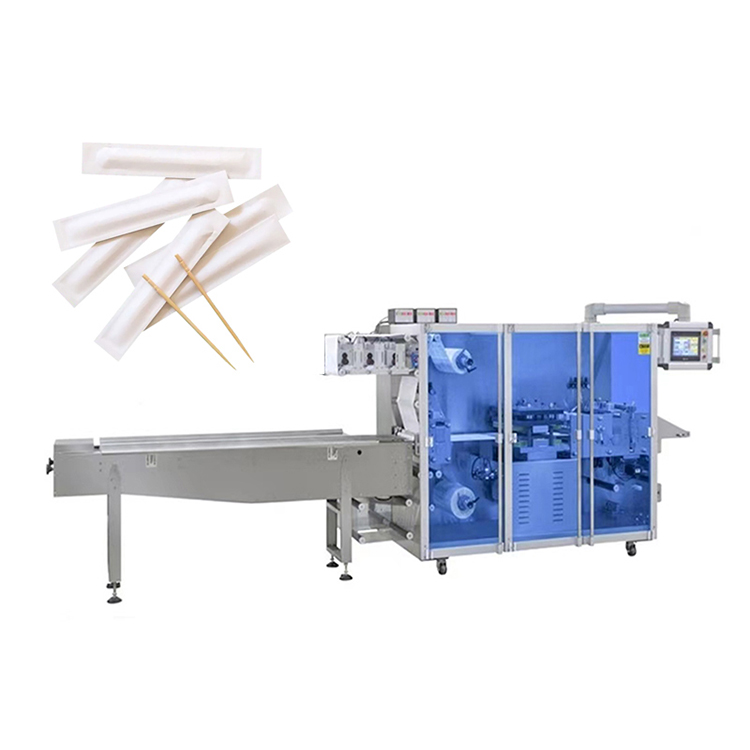

Suitable for packaging hardware, stationery, toys, dinnerware, commodity, cosmetics, rubber products, auto parts, medical equipment, medicines, etc.; For example: shaver, batteries, electronic products, flashlight, lamp bulb, clean ball, foot pat, 502 glue, AB glue, spark plug, brake pad; correction fluid, eraser, pencil sharpener, stapler, ball-pen, solid gum, USB flash disk, card, toy card, chopstick, small spoon, toothbrush, dental floss, lipstick, facial mask, car perfume, syringe, injection, first-aid packet, safflower oil, essential balm, protect baby dan, kyushin pills etc.

High Frequency Plastic Paper Blister Card Heat Sealing Packing Machine Main performance structure features

■ Adopting such packaging forms as positive/negative pressure forming, butterfly hole punching (optional), cutting, feeding, paper card feeding, thermal sealing, finished products conveying etc, is features by simple structure and convenient operation.

■ It adopts 304 stainless steel cover, conforming to GMP requirements. It is featured by beautiful appearance and convenient cleaning.

■ It adopts imported frequency conversion speed adjustment, color touch screen (man-machine interface) and PLC control system. With high output, low noise, clearer and more convenient operation, and high automation degree, the machine is more user-friendly.

■ Servo motor stepless travel control is adopted. The Travel adjustment is simple and mold replacement is convenient.

■ Photoelectric control is adopted. When the PVC sheet is used up or the paper card is insufficient, the buzzer alarm will be sent.

■ The whole machine adopts split design, so as to facilitate transportation and traveling in and out the elevator.

■ The winding plastic sheet feeding device is used to save large amounts of packaging materials.

■ The mold and automatic feeder can be designed according to user requirments and products to be packaged.

Main technical parameters

|

Punching speed (standard version 300 x 98 x 30mm) - five cards 5 |

Paper / plastic 15 times / minute |

|

|

Production capacity |

Paper/plastic 4500 times/hour |

|

|

Feed stroke optional range |

30-280mm |

|

|

Formed area |

470-220mm |

|

|

Forming depth |

Plastic 40mm (Special requirements 65mm) |

|

|

Forming up/down heating power |

2.2kw ( x2 ) |

|

|

Heat sealing heating power |

4.5kw |

|

|

main motor power |

1.5kw |

|

|

Total power of the power supply |

Three-phase four-wire 380v 50hz (200v 60hz) 12.8kw |

|

|

Air pump volume flow |

≥ 1m3 / min |

|

|

Packaging material |

Plastic hard sheet (special made of PET structure) |

≤ 0.2-0.5x500mm |

|

paper card |

≤ 500x300x0.5mm |

|

|

Dimensions |

5900x980x1850mm |

|

|

Total Weight |

2600kg |

|

|

|

|

|

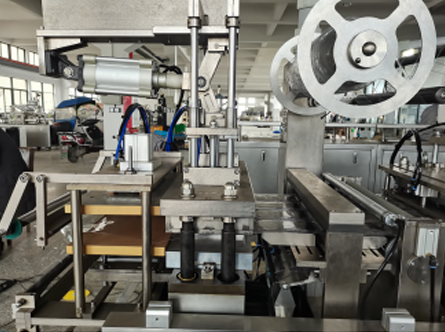

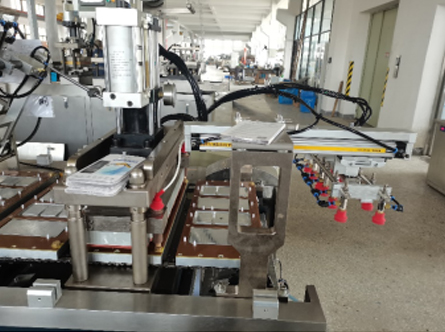

Machine Photo

|

Forming Station (As per product shape) |

Cutting Station and Waste Material Winding |

Formed tray sucked to Module |

|

Paper Card Automatic Feeding |

Heat-seal Station and Finished Product Output (Suction system as per customer request) |

|